In terms of practices and priorities, most heavy duty industrial fields are decidedly old school. They often make use of the same methods and machinery that was around decades ago, and do so with great pleasure. Of course, this is understandable, as a healthy suspicion of the unknown is a quality that has kept many of these companies alive throughout the years. They are used to resisting the too good to be true pitches that the manufacturers of hoist devices seem to make every year, as they know that a lot of these machines are exactly that: too good to be true. Not buying in to fads and trends that look good but may potentially backfire is what allows a lot of these companies to guarantee a higher quality of service than their more modern minded competitors.

Of course, a resistance to modern innovation is a double edged sword. Modern technology can ultimately be a huge boon to those in the manual labor dependent fields. It can make completing tasks much easier and more efficient. The downside to resisting all new technological developments it that it also makes it easy to entirely miss beneficial types of technology that have very few downsides but offer many advantages. This ends up amounting to what is more or less self sabotage, as competitors that may not be as careful with their technology vetting may end up still getting ahead in the end because they are willing to adopt the types of technology that gives them a major edge.

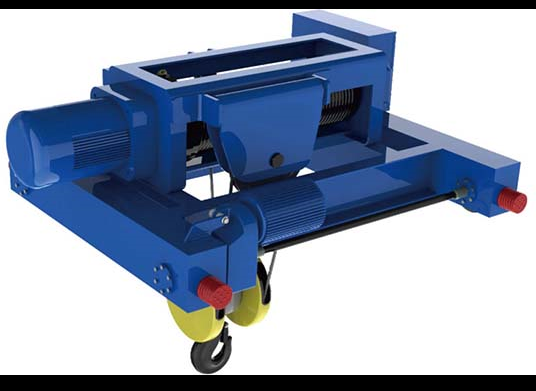

One such piece of machinery is the heavy duty hoist. There are still many industries in which manual lifting, with perhaps the help of a dolly, is still common practice. These industries require that workers use their muscular strength in coordination with other employees to lift some very heavy objects. This is a decidedly inefficient way to lift things, as machines can lift loads that humans can only handle a small fraction of, all without getting tired or worn out after a single task. In this sense, using a heavy duty hoist is just so much more efficient than using human labor to accomplish the same task, as it expedites the job and cuts back on downtime.

Even more importantly, using heavy duty hoists instead of human strength to lift heavy objects can reduce the incidence of injury and even death in heavy duty industries. People who lift heavy objects often struggle to keep these loads balanced. This puts heavy loads at risk of toppling over and crushing workers or pinning them down. Long term heavy lifting also has its own drawbacks. Over time, lifting overly heavy objects can take its toll on the spine and joints, causing serious problems in the long run. By using a heavy duty hoist, employers can make sure that workers are safer in their day to day tasks, as well as less likely to develop health issues over a span of time. want buy one? click http://ellsenhoist.com/heavy-duty-hoist/.