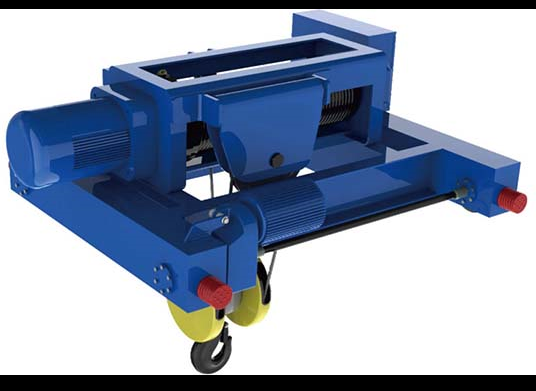

Working in the building industry could be highly dangerous for many laborers, especially if the machine has not undergone the appropriate assessment. To ensure the area is actually a safe workplace void for any health and safety risks, it is crucial that all of the facilities and equipment are of the best meeting all regulations. This short article will examine one of the more important varieties of equipment – an 2 ton overhead crane of Ellsen- and discusses the items to consider when choosing the optimal crane for purchase.

Exactly What Is An Overhead Crane?

Before taking into consideration different factors to choosing an overhead crane, it is vital that you is aware of what an overhead crane supplier is and its particular function. The key reason for any crane would be to lift and move masses from a single portion of the construction site to a different one. The overhead crane, often known as a double girder EOT crane, is considered the most common type of crane located in all industrial settings. It includes two sections known as the traveling bridge and the hoist. The bridge is some parallel runways that facilitate movement in the crane up and down whereas the hoist may be the factor that facilitates the lifting of objects. The hoist moves down the bridge and it is controlled with an engine at the base of the crane.

What Considerations Has To Be Made When Picking An Overhead Crane?

1. The Load

In choosing the ideal overhead crane, it is vital that you simply take into account the weight in the equipment. Weight is important for two specific reasons: firstly, the body weight from the overhead shop crane devices itself needs to be appropriate for the development site never to damage the spot. Secondly, the extra weight must be able to balance the extra weight of the item being hoisted in correspondence with the crane. Consequently the load of your object being lifted will not be beyond the equipment inducing the crane itself to topple. This short article handles the two ton overhead crane therefore, it is important that this construction area be suitable for a weight of 2 tons. The objects being lifted ought to be best for 2 tons to protect yourself from placing unwanted pressure around the crane.

Visit this website http://ellsenoverheadcraneservice.com/2-ton-bridge-crane-sale/ to know more information about Ellsen’s 2 ton bridge crane with high quality and low price.

2. The Height

When choosing a crane, it is actually essential to see how high the objects lifted will have to be hoisted. To have an effective and successful carry it is needed that the object is lifted first and foremost other items in order to avoid any obstructions. To make sure this sort of success is achieved, it is essential that the 2 ton overhead crane be tall enough to lift things to the proper height without the obstructions. This calls for measurement in the site along with the crane prior to making any purchases.

3. The Latching System

To make certain that all objects are safely and successfully relocated, it is strongly advised which you examine the latching system of the hoist. The connection should be considered from the perspective of safety first and various regulations have to be applied prior to making any purchases. You may not wish to be halfway through a project only to experience a faulty connection.