The tyre recycling plant cost might serve to dissuade you from buying one until you learn more about the operation. You see, those waste tires really turn into treasure in terms of valuable resources that can be used to make money. You might even use some of those resources yourself, in fact, some of the oil that you get from the process can fuel the machine, keeping your operating costs low.

One important thing about starting a tyre recycling business is to get a reasonable tyre recycling plant cost. There are just so many ways you can start making money off of those waste tires. You plan to find out more about waste tyre recycling plant prices, and that’s pretty much the sum of your investment. The rest of the time, you’re going to be making money. You do need to keep a supply of waste tires around to feed the machine, but that shouldn’t be all that difficult considering most everyone is simply throwing them away.

If you have a business that maintains a space full of waste tires that is continuously dumped, then now you can plan to recycle them. And you can free up all of that space, perhaps using it for something else. And with all of the money you’re making thanks to your recycling efforts, you can start growing your business. It’s going to be quite nice having that kind of opportunity, don’t you think? Beston Youtube Channel has some videos for your reference.

It’s time to kick your recycling efforts into high gear. Maybe you’ve actually got waste plastic lying around, too. What would really be neat is if you could make this a community effort? You know there are so many waste tires. And you know there is so much waste plastic, too. Get people, including business owners, in your community to bring their waste tires and waste plastic to you. You could make this a full-fledged community recycling effort.

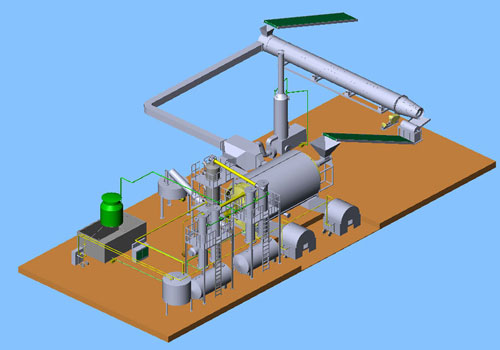

Many companies are discovering just how profitable the tyre pyrolysis plant for sale can be with the right plan in place. You’re going to come up with a plan for your company, and you’re going to make sense of this investment. While you still have to talk to manufacturers and find out more about pricing, the profits are never ending once you get the plant in full swing. You just keep making money off of everything you recycle.

You could determine what you want to do to compensate people for their efforts, and you could be recycling tons of tires and a lot of waste plastic. Think about what that would mean for your business. Beston Group is a professional pyrolysis supplier. Consider what you’re going to do with the rest of the pyrolysis oil, and then think about where you will take the extra steel. You need to make plans to use the hydrocarbon gas in house, and then you can figure out who needs the carbon black.

The oil runs the tyre oil plant, so you don’t have to worry about any more costs, save for occasional maintenance and any manpower required to oversee your operations. The rest is profit, and you’re going to find a way to recycle as many tires as possible. Keep those tires coming through, and free up your community of waste plastic so that you can make a difference.