There’s no denying that an electric hoist (Polipasto Eléctrico) is an essential piece of equipment in many industries. In this guide, we’re going to give you a broad overview of electric hoists, so you will soon understand why they are such an advantage. With this in mind, let’s learn more.

First of all, there are many different types of lifting hoist (diferentes tipos de polipasto de elevación) available. But the electric variety has to be the most efficient and convenient, especially if you are planning to lift heavy loads on a regular basis. Most people who perform a great deal of manual labor will know the risks that heavy lifting can present, so if you don’t want to run the risk of putting your back out, investing in a quality electric hoist is an absolute must.

Fortunately, electric hoists have become more affordable than ever before, so they are well within the price range of most small businesses. But what kind of features can expect to see a quality electric hoist?

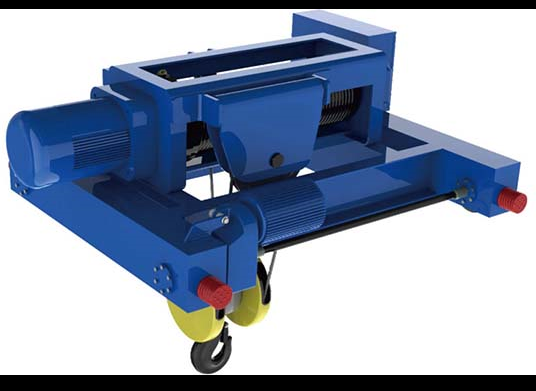

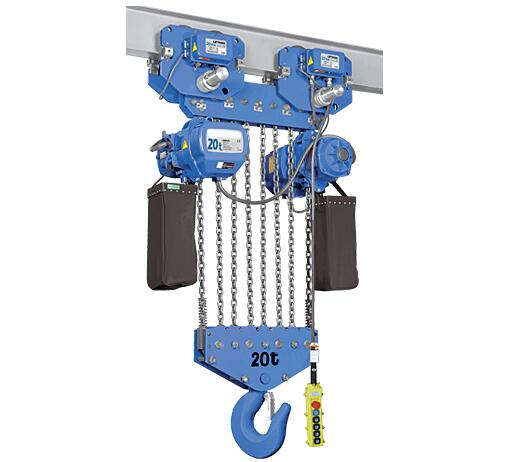

To begin with, you will need to pay close attention to the maximum lifting capacity (capacidad de carga máxima) of your hoist. It’s safe to say that there are many different electric hoists currently available in the marketplace, and some of them will be best suited to smaller loads of up to 500 kg (hasta 500 kg), while some of the bigger hoists can comfortably hold several tons or more.

Next, you want to pay close attention to the operation of the hoist. The biggest benefit of investing in an electric hoist is the fact that you will be able to use a simple hand controlled interface that will give you complete control over the operation of your hoist.

As you’re expect, this is a huge advantage compared to using a manually operated hoist, and once you have switched to electric, you certainly will not want to go back to the lesser technology.

In most cases, you can expect a quality electric powered (con alimentación eléctrica) hoist to be easy to install as well. So many people are finding them useful for small business enterprises or automotive garages.

You’ll also want to look at the overall durability and rugged construction of the hoist. Of course, if you are only using the machine on an occasional basis (de forma ocasional), this may not be much of a concern. But for those businesses that rely on an electric hoist day in day out, it’s well worth spending the extra cash to purchase a hoist that will last you for many years.

Finally, you will need to familiarize yourself with the various safety features that come pre-installed with your electric hoist. In general, you can expect to see some form of capacity limit, as well as a range (gama) of security features that make sure the load cannot come detached from the hoist during a lift.

Conclusion

Overall, it’s clear to see that investing in electric hoist is a smart move for any business that’s in need of an efficient and effective way to lift heavy goods without having to perform all of the manual labor (labor manual) by yourself.